Quenching Oil Filtration Systems Manufacturer, Supplier, Exporter in Pune, Maharashtra India.

Quenching is a rapid way of bringing metal back to room temperature after heat treatment to prevent the cooling process from dramatically changing the metal's micro structure. Metalworkers do this by placing the hot metal into a liquid or sometimes forced airWhat happens to your quench oil over time ?

Advantages Of Filtering Quenching Oil

Quenching Oil - www.youtube.com/watch?v=xB6mS8NrGI8

Quenching Oil Filtration - www.youtube.com/watch?v=A59Ls3VdtrE

Customer Feedback – Hasmukh bhai – Div Heat Treatment, Rajkot -

www.youtube.com/watch?v=nE7hWpD4Ip0

Quenching oil filtration in continuous process. Trial in Sansera Engineering Private Limited, Chakan Pune. -

www.youtube.com/watch?v=D0D8W_Y77Hg&feature=youtu.be

Bhagyashree Accessories Pvt. Ltd. Incorporated in 1994 is leading manufacturer of centrifugal oil cleaners and oil filtration systems. Being an OEM supplier in India and having a global supply experience

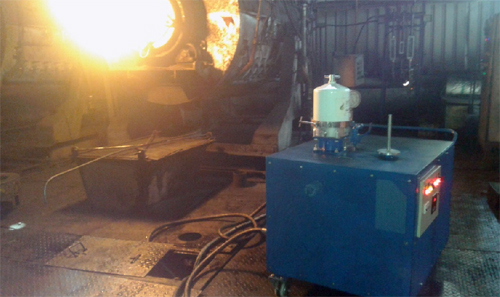

BAPL Super_Kleen200P system installed in a plant of M/s Sham Engineering in Jamshedpur.

Let us help you to do

We Offer Various Models For Oil Filtration As Follows

| Sr.No. | Model | Flow Rate | Dirt Holding Capacity | Type Of Discharge | Type Of Discharge |

|---|---|---|---|---|---|

| 1 | Super_Kleen50 | 500 LPH | 0.5 Kg | Gravity | Upto 1000 Litre |

| 2 | Super_Kleen50P | 500 LPH | 0.5 Kg | Pressurized | Upto 1000 Litre |

| 3 | Super_Kleen200 | 1000 LPH | 2 Kg | Gravity | 1000 - 4000 Litre |

| 4 | Super_Kleen200P | 1000 LPH | 2 Kg | Pressurized | 1000 - 4000 Litre |

| 5 | Super_Kleen600 | 4200 LPH | 6 Kg | Gravity | 4000-10000 Litre |

| 6 | Super_Kleen600P | 4200 LPH | 6 Kg | Pressurized | 4000-10000 Litre |

| 7 | Super_Kleen600 X 2 | 8400 LPH | 12 Kg | Gravity | Above 10000 Litre |